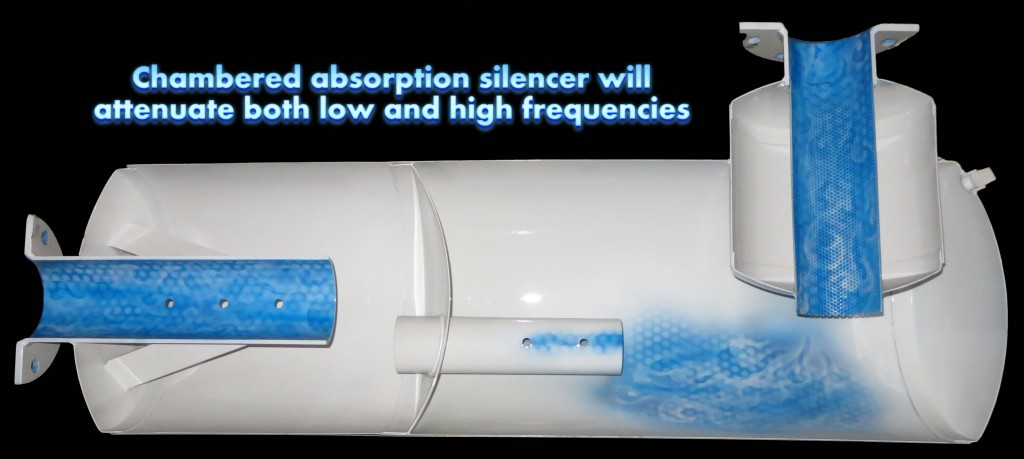

Rotary Blower Discharge Silencers Discharge silencers are essential to a good system performance on all rotary blower systems. Normally, for good silencing, the discharge silencer should have an internal volume to blower displacement of 18 to 1.

Rotary Blower Intake Silencers Intake silencers effectively reduce the noise and destructive low frequency pulsations that can be detrimental to surrounding equipment and personnel, as well as neighbors. The noise and/or pulsation energy generated at the blower inlet is a function of both blower speed and blower size.

Discharge Silencer and Base The PD package provides a discharge silencer and a base on which the blower, motor, and belt guard are mounted as an integral part of the silencer. The PD design reduces labor and the overall cost of assembling small blower packages.

Vacuum Pump Separator Silencers Vacuum Pump Separator Silencers are normally used on wet vacuum systems to reduce the discharge noise and simultaneously separate the liquid, which can be recovered or piped to a drain.

Fan Silencers Fan Silencers are designed as an effective treatment of intake and discharge noise generated by the blower fan by using a high volume, low pressure drop, absorption type silencer.

Vent Silencers Vent Silencers utilize one or two stage diffusers located at the silencer inlet to reduce the noise of vent valves and safety valves releasing high pressure gases into the atmosphere.

Engine Silencers Engine Silencers include Chamber Engine Silencers (Engine intake and exhaust), Resonator Silencers (Low pressure drop silencers for turbo charged engines), Spark Arresting Silencers (for marine applications and areas where fire hazards may exist), and Low Profile Silencers.

Centrifugal Compressor Silencers Centrifugal Compressor Silencers are designed to absorb the high-frequency intake and discharge noise of centrifugal compressors constructed of heavy cast iron.