- 15April

-

Case Study- Required noise level 80-85 dBa

The Requirement: A large mobile unit to vacuum earthen material into a vacuum receiver that rides on elevated rails to unload into dump trucks. This power unit would need to be disassembled 2-3 times per year and moved to different locations along different areas of the project.

The Design: The final design was a unit that would be powered by a 160 HP, 4.5 L, Cummins QSB, Tier 3, diesel engine. The engine would be directly coupled to a Robuschi 105 P-D Vacuum Blower. The package was designed on a skid style base, to be portable. The skid would also contain a diesel fuel tank, two blower intake silencers, two blower discharge silencers and a silencer for the engine exhaust.

Normal operation of the unit would produce 2200 ICFM and 22”Hg @ 2100 RPM.

The Issues: The specification required the unit to operate within a very limited noise criteria because it would occasionally be located in residential areas. The operating skid package produced approximately 110-120 Decibels. This would require the entire power unit skid to be enclosed within a sound enclosure which creates the second issue: heat gain. The normal operating temperature of the diesel engine was 202°F along with an exhaust temperature of 932°F. The Robuschi Blower also had temperature rise of approx 200°F and the maximum design ambient temperature was 122°F. The entire unit also needed to fit in a shipping container completely assembled.

The required noise level was 80-85 dBa and operating temperature needed a temperature rise under 30°F.

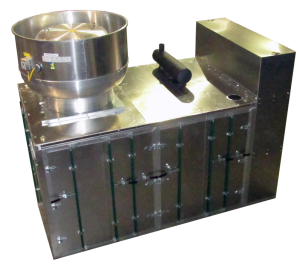

The Solution: Pathfinder Systems designed a structural frame utilizing 3×3 aluminum tubing to give it the durability needed to be repeatedly disassembled, transported, and re-assembled. It was sheeted in aluminum and high performance acoustic foam lined with heat resistant film to protect it from the heat of the diesel engine. Nine doors offered complete access to all of the equipment inside the enclosure for service and maintenance. Pathfinder also supplied the engine silencer which was mounted on the roof of the sound enclosure. The thermal gain was calculated and it was determined that 16,400 CFM was needed to keep the total heat gain under 15°F. This would require an air inlet box large enough to accommodate the air flow for the exhaust fan, and for the engines radiator fan, but engineered not to affect the overall attenuation.

The Solution: Pathfinder Systems designed a structural frame utilizing 3×3 aluminum tubing to give it the durability needed to be repeatedly disassembled, transported, and re-assembled. It was sheeted in aluminum and high performance acoustic foam lined with heat resistant film to protect it from the heat of the diesel engine. Nine doors offered complete access to all of the equipment inside the enclosure for service and maintenance. Pathfinder also supplied the engine silencer which was mounted on the roof of the sound enclosure. The thermal gain was calculated and it was determined that 16,400 CFM was needed to keep the total heat gain under 15°F. This would require an air inlet box large enough to accommodate the air flow for the exhaust fan, and for the engines radiator fan, but engineered not to affect the overall attenuation.The finished enclosure had a db reading of 80.3 dBa @2100 RPM and an operating engine temperature range of 176-185°F.

Posted by PathfinderSystems Posted on 15 Apr

Post Comments 0